Zipper Pouch 4 Side Sealing Packing Machine

What is zipper pouch 4 side sealing packing machine?

A zipper pouch 4 side sealing packing machine is a specialised piece of packaging equipment designed to create resealable pouches with a zipper closure. This type of machine simultaneously seals all four sides of a pouch, adding a zipper feature that enables the pouch to be securely closed after the initial opening. Here’s how it functions and serves various packaging needs:

Four-Side Sealing: The machine seals the pouch on all four sides, creating a strong barrier to protect the product inside from environmental factors such as moisture, air, and contaminants, which is essential for maintaining product quality.

Zipper Mechanism Installation: During the packing process, a zipper strip is applied to the pouch, which allows consumers to easily open and close the pouch multiple times. This feature enhances product convenience and freshness, particularly for food items and consumer goods that are not used in a single session.

Material Handling: The machine is typically capable of handling various flexible packaging materials, which allows for the production of durable and attractive zipper pouches suitable for a wide range of products.

Automation: The entire process, from feeding the material to sealing and applying the zipper, is automated, resulting in consistent pouch quality and increased production efficiency.

Zipper pouch 4 side sealing packing machines are highly valued in industries where product preservation and consumer convenience are top priorities. The resealable nature of the zipper pouch not only enhances the user experience but also helps in reducing waste by allowing the contents to be stored securely after opening.

Name | Zipper pouch 4 side sealing packing machine |

Material | Film,laminated film, coated paper |

Width size | 2 lane packing, max width 350mm |

Speed | 80-140pcs/min |

length | customized |

Piece per packaging | Customized |

Lane of output | 2 output per cut |

Sealing | Mold sealing, ultrasonic seal of zipper |

Power | 14kw |

Machine size | 6200*2000*2100 mm |

Machine weight | 2500kg |

Finished Packaging

square packaging

Round edge packaging

Frequently Asked Questions about The Machine.

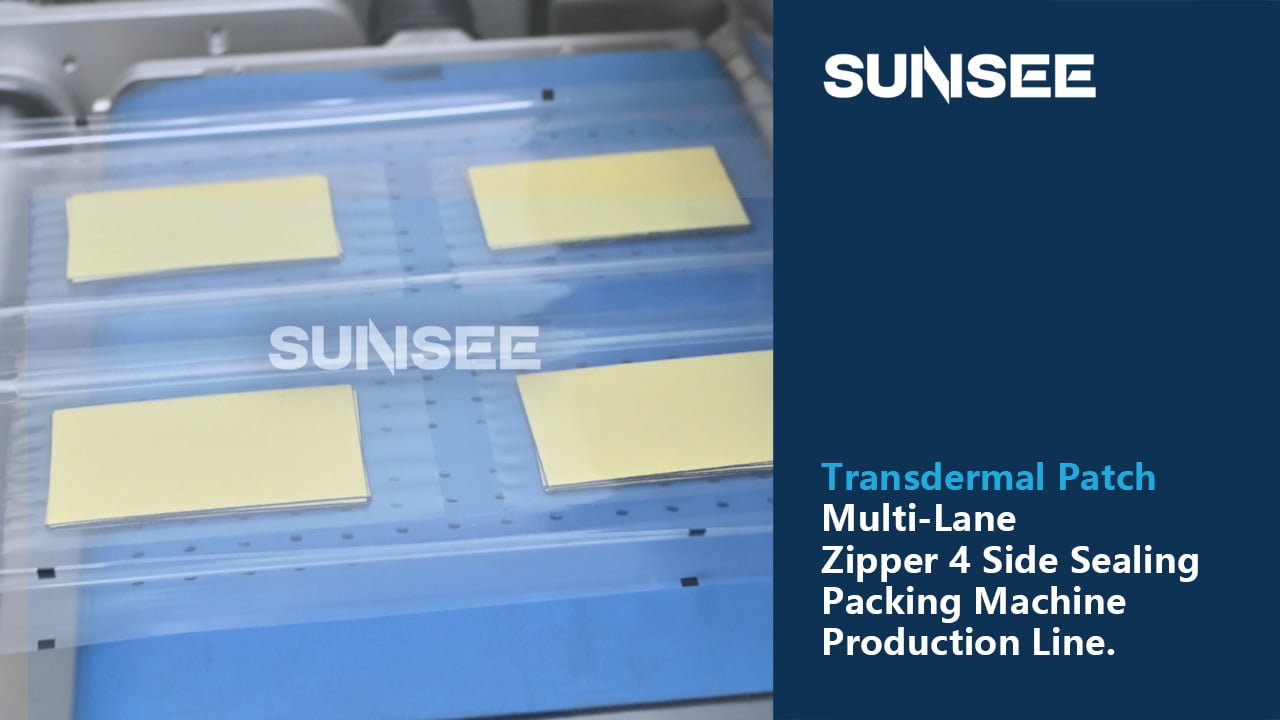

The Sunsee zipper pouch 4-side sealing packing machine is an integrated, fully automatic system designed for the efficient processing and packaging of transdermal patches. The machine combines the intricate process of die cutting transdermal patches with the subsequent packing into zipper pouches. Here’s how it operates:

Die Cutting Process: Initially, the machine performs precise die cutting of transdermal patches. Clients can customize the size and shape of the die cut according to their specific product requirements. This step ensures that each transdermal patch is cut accurately to the desired dimensions.

Automatic Feeding and Packing: After the patches are die-cut, they are automatically fed into the packing section of the machine. Here, a film is used to create individual pouches, each designed to contain a single transdermal patch.

4-Side Sealing and Zipper Mechanism: Once a transdermal patch is placed inside a pouch, the machine securely seals the pouch on all four sides. This sealing process guarantees the patches are airtight and protected from external elements. Additionally, a zipper mechanism is incorporated into each pouch, making it resealable for consumer convenience.

Final Processing: After sealing, the individual pouches are cut, separated, and undergo a final quality check. The fully packed and sealed transdermal patches are then ready for distribution and sale.

Sunsee’s zipper pouch 4-side sealing packing machine, tailored for transdermal patch packaging, offers significant benefits to our clients. Key advantages include:

Fully Automated Production: Equipped with a customizable auto-feeder system, our machine ensures a seamless, fully automatic production line. This automation leads to increased efficiency, reduced labor costs, and a streamlined packaging process, directly benefiting your operational throughput.

Versatile Customization: We provide the flexibility to customize the machine for various operational needs, including options with or without die cutting and multi-lane packing capabilities. This adaptability allows you to tailor the packaging process to your specific product requirements, ensuring optimal efficiency and precision.

Ideal for Transdermal Patches: Specifically designed for transdermal patch packaging, our machine guarantees precision, maintaining the quality and integrity of each patch. The four-side sealing and zipper mechanism ensure each patch is securely packed, enhancing product longevity and consumer satisfaction.

Sunsee’s customizable auto feeding system significantly enhances the packing process by adapting to different types of patches with specialized mechanisms. For gel patches, we employ a rotary feeder designed to handle their delicate nature efficiently, ensuring smooth and accurate placement into the packaging. For harder patches, our system includes a precise pick-and-place mechanism, adept at handling more rigid materials without compromising the speed or accuracy of the packaging process. This tailored approach not only optimizes the packing efficiency for various patch types but also ensures the integrity and quality of the patches throughout the packaging cycle.

Absolutely. Sunsee’s packing machine is designed for versatility, easily accommodating a variety of pouch sizes and types. This adaptability allows for the customization of packaging to meet diverse product specifications and branding requirements. Whether you need smaller pouches for individual patches or larger ones for bulk packaging, our machine can be adjusted to suit these needs, ensuring a flexible solution for your diverse packaging demands.

2 lane output, with 100-120pcs/min/lane.

Sunsee’s machine ensures top-notch packaging durability and quality by incorporating advanced features.

It includes sensors to verify the presence of material in every pack and to check the thickness of each patch, ensuring consistency and precision.

A sophisticated temperature control system maintains optimal heat for sealing, preserving the integrity of the packaging.

Additionally, the machine is equipped with a robust system for high-speed operation and safety, providing reliable, efficient packaging solutions that directly benefit our customers by enhancing productivity and product quality.

Sunsee’s packing machine is designed for easy integration into existing production lines. Its versatility allows it to be seamlessly combined with additional equipment, such as a box packing machine, to create a comprehensive packaging solution. This modularity ensures that the machine can complement your current setup, enhancing overall efficiency without the need for extensive modifications. By adding such capabilities, it streamlines the packaging process, from individual pouch packing to final box packaging, aligning perfectly with your production flow and increasing operational productivity.

Customized: auto feeder

- Customizable Feeders: Adapts to various patch types.

- High Speed: Accelerates production significantly.

- Labor Efficiency: Reduces manual workload.

Customized:box packing machine

Discover the future of packaging efficiency with our Online Box Packing Machine. Tailored for transdermal patch manufacturers, this innovative system offers seamless 4-side sealing and optional box packing capabilities.