Flow Wrap Packing Machine

The Flow Wrap Packing Machine, also known as the pillow-type or horizontal packing machine, is a versatile equipment designed for heat-sealing various products using films. Featuring servo or inverter control and user-friendly touchscreen operation, it streamlines the packaging process efficiently.

Application:

The Flow Wrap Packing Machine is designed to efficiently package a wide range of products, including:

Food items such as candies, bread, cookies, chocolate bars, ice cream, vegetables, and more.

Medical products like plaster patches, pills, foam patches, stickers, bandages, tooth stickers, surgical products, masks, and more.

Daily use products including paper cups, lunch boxes, masks, cards, toothpaste, brushes, pens, gloves, and various others.

Hardware items such as door handles, keys, locks, auto parts, screws, banners, pipes, and more.

Our versatile machine is suitable for packaging diverse products across multiple industries.

How does the flow wrap packing machine work?

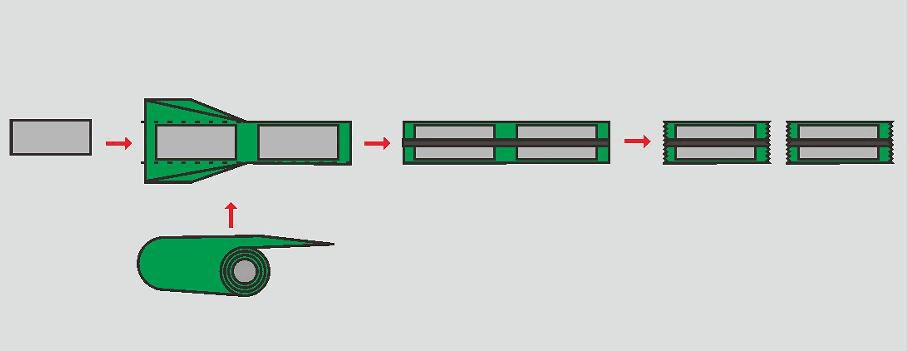

The Flow Wrap Packing Machine operates in the following steps:

Material Feeding: Material is loaded onto the conveyor belt manually or through an automatic feeding device.

Film Entry: The material enters the packing film horizontally.

Forming: At the film entrance, a forming device folds the film to cover the products.

Sealing: A heat-seal wheel seals the film’s edge, creating a central seal.

Cutting: A blade seals and cuts the film at both sides of the package.

Product Exit: The finished products smoothly exit the machine.

model | XZB250 | XZB350 | XZB550 |

Packing film | OPP,BOPP,laminated film | ||

max film width | 250mm | 350mm | 550mm |

capacity (pcs/min) | 30-100 | ||

film thickness | 0.03-0.06mm | ||

bag length | 50-250mm | 50-350mm | 50-550mm |

packing width | 30-200mm | ||

packing height | ≤60mm | ≤60mm | ≤80mm |

Let's optimize your operations together.