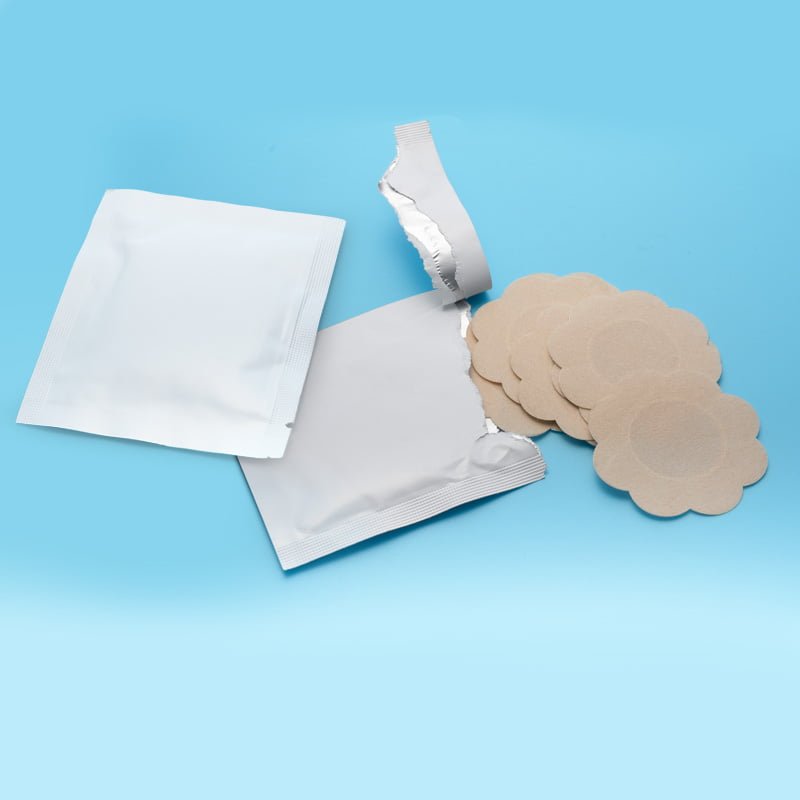

Application

transdermal patch 4 side sealing packing machine

Rapid test kit 4 side sealing packing machine

Hydrogel Patch 4 side sealing packing machine

Main Configuration

A 4-side sealing packing machine is an industrial piece of equipment used for packaging various types of products. This machine is specially designed to seal all four sides of the packaging material, creating a completely enclosed, airtight packet. This is particularly useful for products that require high levels of protection against external contaminants, moisture, and air.

Output | 80-150pcs/min |

Packing size | L 60-200mm, W 60-200mm, H 1-10mm |

compressor | ≥0.1m3/min |

voltage | AC 220V 60HZ(customized) |

power | 7KW |

weight | 2600kg |

Dimension | L*W*H 5000×1660×1430㎜ |

Want to Know more.

Table of Contents

How does the 4 side sealing packing machine working?

Feeding: The machine’s auto-feeding system accepts the product, which could range from transdermal patches to hydrogel patches, plasters, rapid test kits, or teeth whitening strips.

Pouch Formation: The machine forms a pouch from a roll of packaging material such as plastic, foil, or paper.

Filling: The product is then filled into the film.

Sealing: All four sides of the pouch are then sealed securely, ensuring the contents are well-protected.

Cutting: The sealed pouch is then cut from the roll and is now ready for labeling and further processing.

What material can be used on 4 side sealing packing machine?

The 4-side sealing packing machine is designed with versatility in mind, capable of handling various types of packaging materials. Below are the most commonly used materials compatible with this machine:

Plastic Films

- Polyethylene (PE): Widely used for its low cost and excellent sealing properties.

- Polypropylene (PP): Known for high-temperature resistance and is commonly used for products that require sterilization.

Laminates

- Polyester/Polyethylene (PET/PE): Offers excellent clarity and stiffness, often used for retail packaging.

- Polyester/Polypropylene (PET/PP): Suitable for applications requiring higher temperature resistance.

Metalized Films

- Metalized Polyester (MET-PET): Used for products requiring a higher barrier against moisture, light, and oxygen.

- Metalized Polypropylene (MET-PP): Offers similar benefits as MET-PET but with better heat resistance.

Foil-based Materials

- Aluminum Foil Laminates: Commonly used in pharmaceuticals for products that require maximum protection against light, moisture, and oxygen.

Paper-based Materials

- Kraft Paper: Often used for organic or eco-friendly products.

- Coated Paper: Provides a good printing surface and is commonly used for consumer goods.

Specialty Materials

- Biodegradable Films: For businesses focusing on sustainability, various biodegradable options are available.

- Nylon: Known for its excellent puncture resistance, commonly used for medical applications.

Important Considerations

Sealing Temperature: Different materials require different sealing temperatures. Make sure the machine’s settings can accommodate your chosen material.

Barrier Properties: Choose the material based on the barrier properties required for your specific product.

Regulatory Compliance: Ensure that the materials you select are compliant with industry regulations, especially for food and pharmaceutical packaging.

By understanding the various material options and their respective properties, you can make an informed decision that aligns with your packaging requirements and quality standards.

What is the limitation of 4 side sealing packing machine?

While 4-side sealing packing machines offer numerous advantages such as high-quality seals and efficient packaging, it’s essential to be aware of their limitations to make an informed purchasing decision.

Speed Constraints

- Limited Speed: While the material shape is unregular, can not equipped with auto feeder, and speed will go to 60-80pcs/min.

Material Restrictions

- Limited Flexibility: Not all materials can be used efficiently. Each material has its own sealing temperature and pressure requirements that need to be adjusted manually.

Size Limitations

- Package Dimensions: There’s a limit to the size of the package that can be accommodated. This could be a drawback if your product range includes very large or irregularly shaped items.The standard height is >15mm.

Cost Implications

Initial Investment: These machines can be costly to acquire, making them a significant initial investment.

Maintenance Costs: Though generally low-maintenance, any specialized parts that need replacement can be costly.

Technical Skill Requirements

- Operational Complexity: Operators need some level of technical expertise to run the machine efficiently and troubleshoot issues.

Energy Consumption

- High Energy Usage: Depending on the machine’s specifications, it may consume a considerable amount of electricity, especially during extended periods of operation.

Space Requirements

- Footprint: The machine can be bulky and may require a substantial amount of floor space, which could be a constraint in smaller facilities.

Limited Versatility

- Single Packaging Type: The machine is specialized for 4-side sealing, which means you cannot switch to other types of packaging without additional equipment.

Understanding these limitations can guide you in deciding if a 4-side sealing packing machine is the right fit for your operational needs. It may also prompt considerations for complementary equipment or systems to offset these constraints.

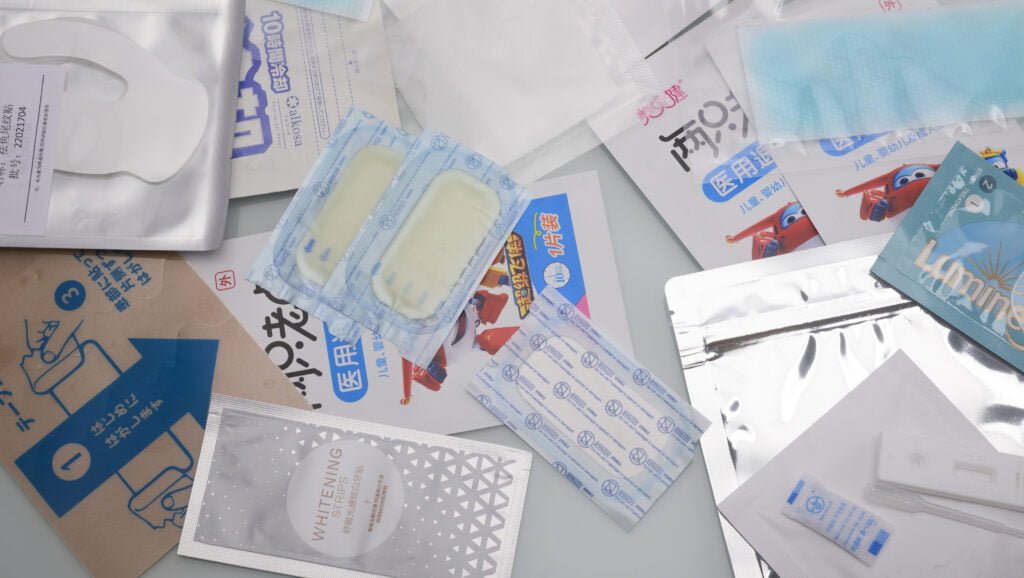

What is the application of 4 side sealing packing machine?

The 4-side sealing packing machine is a versatile piece of equipment that can be used across multiple industries for various types of products. Below are some key areas where this machine is commonly applied:

Pharmaceutical Industry

Transdermal Patches: For medications that need to be absorbed through the skin.

Plasters: Especially useful for sealing medicated plasters that require an airtight, sterile package.

Healthcare Sector

Hydrogel Patches: Used for wound care or as cooling patches.

Rapid Test Kits: For medical diagnostics, ensuring kits are sealed securely to maintain sterility.

Personal Care

Teeth Whitening Strips: Ensuring the whitening gel remains potent and uncontaminated.

Cosmetic Patches: Such as anti-wrinkle patches, eye patches, etc.

Food Industry

Single-Serve Condiments: Like ketchup, mustard, or mayonnaise.

Nutraceuticals: Such as vitamin sachets or herbal extracts.

Electronics

- Small Components: Like screws, buttons, or other tiny parts that need to be kept free from moisture and dust.

Key Points

High-Quality Sealing: This machine provides a robust 4-side seal, offering excellent protection against external factors like moisture, air, and contaminants.

Versatility: Capable of sealing a wide range of products, making it a valuable asset for different industries.

Customizable: The auto-feeding system can be customized to suit the specific product being packaged, adding an extra layer of flexibility.

Understanding the wide array of applications can help you determine if a 4-side sealing packing machine is the right fit for your business needs.

What is the advantage of packing with 4 side sealing packing machine?

Utilizing a 4-side sealing packing machine offers several distinct benefits that can enhance the efficiency and quality of your packaging operations. Here are some of the primary advantages:

Improved Product Protection

Robust Seal: The four-side seal offers a higher level of protection against external elements like air, moisture, and contaminants, which is crucial for sensitive products.

Tamper-Evident: The secure sealing also acts as a tamper-evident feature, giving consumers confidence in product integrity.

Efficiency and Speed

Automated Operation: With an auto-feeding system, the machine can work unattended, freeing up labor for other tasks.

High Throughput: Typically ranging from 80-150 pieces per minute, this machine can meet the demands of high-volume production.

Material Utilization

Material Efficiency: The machine is designed to minimize waste, thereby lowering material costs over time.

Material Versatility: Capable of handling a wide range of materials, including plastic, laminate, and foil, among others.

Customization and Flexibility

Adjustable Settings: You can easily change settings for seal temperature, pressure, and dwell time, allowing for different material types and product specifications.

Auto-Feeding Customization: The feeding system can often be tailored to suit specific products, adding an extra layer of operational flexibility.

Cost Savings

Reduced Labor Costs: The automation capabilities mean you need fewer workers to manage the packaging process.

Resource Optimization: By reducing material waste and optimizing labor, you achieve long-term cost savings.

Compliance and Quality Assurance

Consistent Quality: Automated systems ensure each package is sealed with the same level of quality, meeting compliance standards.

Traceability: Many models come equipped with features that allow for batch tracking, aiding in quality control and recall procedures.

By understanding these advantages, you can better assess how a 4-side sealing packing machine could fit into your overall operational workflow and contribute to improving both efficiency and product quality.